1 Stamps. Stamps were used in California gold mines around 1850. 2 Rockers. A rocker, also known as a cradle, separated gold from dirt. 3 Pickaxes. Pickaxes were known as the gold standard for early mining in the 1800s. 4 Drills. Miners drilled by hand or used compressed air drills. 5 Pans.

WhatsApp: +86 18037808511

By 2000 bc the process of purifying goldsilver alloys with salt to remove the silver was developed. The mining of alluvial deposits and, later, lode or vein deposits required crushing prior to gold extraction, and this consumed immense amounts of manpower. By ad 100, up to 40,000 slaves were employed in gold mining in Spain.

WhatsApp: +86 18037808511

Mobile Gold Ore Processing Mining Equipment Supplier Price for Small Scale Rock Alluvial Diamond Mine Placer River Sand Mineral Gravity Washing . US / Piece. 1 Piece (MOQ) Type : Gravity Separator; Voltage ...

WhatsApp: +86 18037808511

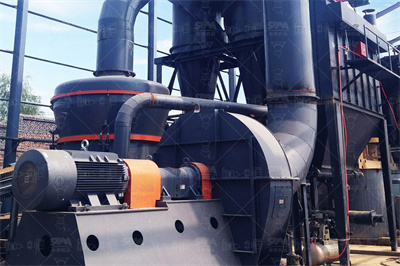

The main gravity beneficiation equipment is jig concentrator, shaking table, spiral separator, and gold concentrator. It can processing various minerals such as gold, copper, leadzinc ore, tantalum, niobium, tin, and tungsten, etc. Strong adaptability, high sorting recovery rate and low cost.

WhatsApp: +86 18037808511

Carbonin leach (CIL) is a simultaneous leach and absorption process. The simultaneous leach and absorption phases of the CIL process were developed for processing gold ores that contain pregrobbing materials such as natural absorptive carbon. These reduce the gold yield by attracting gold meant for the activated carbon.

WhatsApp: +86 18037808511

Gold panning equipment is the most basic type of gear that one needs for gold prospecting. It is simply a metal or copper pan with a slanted bottom used to wash the dirt and gravel from the gold. Some gold panning kits include a gold pan, suction bottle, tiny tubes, a magnifier, tweezers, and a vial, all essential for gold panning.

WhatsApp: +86 18037808511

About Our Process. From the discovery of buried minerals to reclaiming land after closure of a mine, our operations can sometimes span 30 years or even longer. This means we may conduct business in or near a community for decades, and even generations. Throughout that time, Newmont's core values safety, integrity, sustainability ...

WhatsApp: +86 18037808511

This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners ...

WhatsApp: +86 18037808511

Shaking table, also called gold recovery table or gold separation table, is the best fine gold recovery equipment. It can process both gold ore in quartz rock, gold stones, and placer gold. The feeding particle size range of the shaking table is generally between The gold beneficiation is stable and reliable, and the distribution ...

WhatsApp: +86 18037808511

Mining exploitation and its impact on global warming have become significant problems. The main objective of this study is to investigate the impact of mining industry equipment and natural resource demand on global warming in Congo. A crosssectional survey was conducted from October 2021 to July 2022, using a selfadministered questionnaire. The survey was carried out with 1360 respondents ...

WhatsApp: +86 18037808511

Half of the national exports come from the mining and from 1998 the gold is the principal product of national exportation. Beneficiation Plants. Only 5 plants in the study area use modern process equipment and can be considered to have acceptable reliability. These are shown on Table 2 below: Table 2: Operating Plants. Plant Site Location

WhatsApp: +86 18037808511

But then they need to be brought to the surface. Underground specialized mining equipment such as trucks, loaders, diggers etc. are used to excavate the material and are normally hauled to the surface with skips or lifts for further processing. Drilling is normally required to place explosive charges to liberate the minerals from the overburden ...

WhatsApp: +86 18037808511

A spiral chute is used to separate finegrained iron, tin, tungsten, tantalum, niobium, gold ore, coal mine, monazite, rutile, zircon, and other metal and nonmetallic minerals with sufficient specific gravity difference. The sorting process is stable and easy to control, the allowable range of feed concentration is wide, the enrichment ratio ...

WhatsApp: +86 18037808511

Found in Bulgaria are some of the oldest gold artifacts known to mankind, in the Varna Necropolis, a collection of graves built between 4700 and 4200 BC. This finding, dating back nearly 7000 years, provides evidence of the first civilization to use gold mining equipment. Some archeologists claim the Sakdrisi site in southern Georgia, which ...

WhatsApp: +86 18037808511

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in smallscale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE' offers gold mining equipment as well as processing equipment applicable to most base metals such as copper, lead, and zinc.

WhatsApp: +86 18037808511

3. Tanzania 10 TPH rock gold processing plant The material processed by the Tanzanian gold processing plant is rock gold, which is a kind of oxidized gold ore. The gold particle size of the rock is very fine. The production capacity is 10 tons/hour. The feed size is 0125 mm. The plant uses the gravity method. The equipment is configured as a ...

WhatsApp: +86 18037808511

Locating, extracting and processing these natural resources is a multiyear process that involves complex scientific, environmental and social planning. Newmont mission is to build a sustainable mining business while leading in safety, environmental stewardship and social responsibility. Today, we primarily mine gold and copper, as well as ...

WhatsApp: +86 18037808511

CONTACT USA Phone: ( 360 ) 671 7817 Fax: (360) 671 7820 EMail: Goldlands Goldlands Manufactures A Range of Alluvial and Hard Rock Gold Recovery Equipment. Sonic Gold Processor complete alluvial gold extraction machine. Gold Hybrid Wash Plant Trommel Gold Concentrator. Trommels, Helicoids, Complete Wash Plants.

WhatsApp: +86 18037808511

In modern times though, mining for gold is a much more intensive, yet sophisticated process. Most surface, or alluvial gold has been found, which is why gold is mainly mined from the earth today. It's largely a matter of technology and requires much expertise and elaborate equipment. Mining for gold today can essentially be broken down into 9 ...

WhatsApp: +86 18037808511

We offer and recommend our gold recovery training at our USA facility, for no additional cost, when purchasing our gold mining equipment. Large Scale Proven From the Yukon through the Rocky Mountains and into the Jungles, we have designed and manufactured equipment plants / systems processing 1,500+ tons of ore per hour.

WhatsApp: +86 18037808511

The Salton Sea is one of numerous new mining proposals in a global gold rush to find new sources of metals and minerals needed for electric cars and renewable energy. The Lithium Gold Rush: Inside ...

WhatsApp: +86 18037808511

Introduction. Gold is a very rare substance making up only ~3 parts per billion of the Earth's outer layer (imagine 1 billion smarties in one place and only 3 of them were made of gold!). Its rarity and physical properties have made gold one of the most prized of the Earth's natural resources. When gold is found in rocks it is almost always in ...

WhatsApp: +86 18037808511

WIDE RANGE: DOVE Equipment Machinery is a leader and powerhouse in the mining equipment manufacturing industry, producing the largest range of Portable Gold Wash Plants (Portable Gold Processing Plants) for small, medium and large scale mining operations, with the capacity to handle material ranging as below:. EXPLORER ® Portable Alluvial Gold Processing Plants (Portable Gold Wash Plants ...

WhatsApp: +86 18037808511

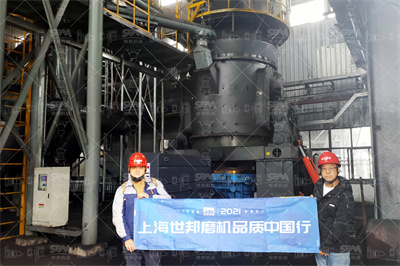

Main Equipment: Ball mill, gold centrifugal concentrator, shaking table Flowchart explanation for 2tph rock gold processing plant This is a 2 TPH rock gold processing plant site from an Egyptian customer, it's configured with a ball mill, gold centrifugal concentrator, and shaking table. Ore in transit bin is sent to ball mill via vibrating feeder and belt conveyor, then grind the ore to ...

WhatsApp: +86 18037808511

Our systems easily master steep inclines, rivers, and roads. Coal, ores, and minerals can be transported on the conveyor belt from the mine to the blending bed in just one hour, even on winding routes up to 25 km long. Energyrecovering systems along the way can utilise downhill sections of your route and feed electricity back into the public grid.

WhatsApp: +86 18037808511

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

WhatsApp: +86 18037808511

employed in artisanal and smallscale gold mining and processing . (e) Strategies for promoting the reduction of emissions and releases of, and exposure to, mercury in ASG mining and processing, including mercuryfree methods . (f) Strategies for managing trade and preventing the diversion of mercury

WhatsApp: +86 18037808511

In the flotation process of the major steps that must be done include the process destruction of rock minerals, milling, flotation, drying, and smelting. 1. Crushing and Grinding stage. 2. Classifying stage are the same as Gravity process. 3. Mixing and Flotation stage. The classified ore gets into mixing tank for fully mixing.

WhatsApp: +86 18037808511