This paper presents the kinetics study of dry ball milling of calcite and barite minerals. The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total ...

WhatsApp: +86 18037808511

The present work is therefore to investigate the grinding process in a tumbling ball mill involving both grinding media and ground powders. The simulations are based on our previously developed DEM model which successfully simulated both dry and wet particle flows in rotating drums [15], [16], [17]. ... The mills are first loaded with steel ...

WhatsApp: +86 18037808511

The present work is therefore to investigate the grinding process in a tumbling ball mill involving both grinding media and ground powders. The simulations are based on our previously developed DEM model which successfully simulated both dry and wet particle flows in rotating drums [15], [16], [17]. Different forms of energy will be analysed ...

WhatsApp: +86 18037808511

This study investigated ultrafine coal grinding performance of four low to moderatecost grinding media in a laboratory stirred mill. Kinetic grinding tests showed that silica beads generated the finest product size with a P 80 of μm from a feed size of μm while having a specific energy (SE) input of 309 kWh/ton. Nonetheless, the ...

WhatsApp: +86 18037808511

The optimization of processing plants is one of the main concerns in the mining industry, since the comminution stage, a fundamental operation, accounts for up to 70% of total energy consumption. The aim of this study was to determine the effects that ball size and mill speed exert on the milling kinetics over a wide range of particle sizes. This was done through dry milling and batch grinding ...

WhatsApp: +86 18037808511

The grinding medium generally used is in the form of balls, rods or cylindrical media called cylpebs. Both steel and ceramic balls are in use depending on the hardness of the rock. For soft ores, pebbles are added or simply autogenously ground with no medium. Both wet and dry grinding is common.

WhatsApp: +86 18037808511

mills presents the energy saving around 30% when compared to tumbling ball mills used for coarse grinding. By applying various methodologies, other researches confirmed the

WhatsApp: +86 18037808511

In continuous wet ball mills, the composition of feed (hard ore or soft ore) to the mill varies continuously, leading to uncontrolled grinding in the mill. In view of this, a new design of the discharge mechanism has been implemented to remove the ground particles of desired particle size fraction with minimum recirculating load (+150 µm).

WhatsApp: +86 18037808511

To investigate the effects of grinding media shapes on the grinding kinetics of ball mill cement clinker, the grinding effects with ϕ20 mm balls and ϕ20 × 20 mm cylinders on six different size ...

WhatsApp: +86 18037808511

The results demonstrated that graphene could significantly enhance the environmental effect of tourmaline. The ball milling method was the optimum preparation method, and the parameters were determined as follows: ball milling speed = 200 rpm and ball milling time = 2 h. The optimum graphene content was % of the mass of tourmaline.

WhatsApp: +86 18037808511

Tumbling mills. Most of the available studies on the investigation of GAs in continuously operated grinding plants focus on closedcircuit operations with tumbling ball mills. For instance, Sottili and Padovani [11] showed that industrial closedcircuit grinding of cement clinker using a tumbling ball strongly benefits from GA applications ...

WhatsApp: +86 18037808511

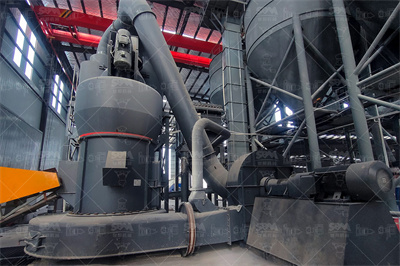

A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics. ... At a mill speed of 20 rpm and rolling resistance of, the maximum translational velocity of particles is m/s, which is 46% lesser than the maximum translational velocity at 30 rpm. ... Effect of lifters and mill speed ...

WhatsApp: +86 18037808511

Energy related research work was carried out by Iwasaki et al. (2006), they studied the effect of three types of media mills, a horizontal tumbling ball mill, vertical agitating ball mill and bead mill on the deformation of spherical copper powder. The particle size distributions were measured before and after grinding and the deformation of ...

WhatsApp: +86 18037808511

The effect of ball mill on the morphological and structural features of cellulose has been described by Okajima and coworkers. 20 They treated microcrystalline cellulose derived from cotton linters in a planetary ball mill at 200 rpm for 48 hours in dry and wet conditions with three solvents (water, toluene, 1butanol). They observed that ...

WhatsApp: +86 18037808511

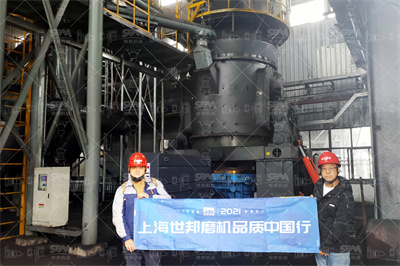

Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding with its finer grinding requirements coming more ...

WhatsApp: +86 18037808511

Vertical Ball Mill. Volume of Barrel: 301300L. Grinding Media Load: 15650L. Motor power: 342kw. Applications: Vertical ball mill can be widely used in electronic materials, magnetic materials, ceramic glaze slurry, ink pigment, food, pharmaceutical and other industries. Email: info Get Price Now.

WhatsApp: +86 18037808511

The speed of the grinding section of these mills is usually 75225 rpm. They operate on the principles of crushing and attrition. Pulverization takes place between two surfaces, one rolling on top of the other.

WhatsApp: +86 18037808511

The work using a vertical shaft stirred mill compared with Bond ball mill, both operated in closed circuit with a classifier, demonstrated a clear trend that on average 30% energy saving can be expected by using the stirred mill to replace ball mill for coarse grinding from a top particle size mm to P 80 less than 100 μm.

WhatsApp: +86 18037808511

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles ...

WhatsApp: +86 18037808511

A laboratory scale planetary ball mill ( Retsch PM400) was equipped with a test rig which enables the observation and recording of the grinding ball motion inside the grinding chamber. A high speed camera was fixed on the sun wheel (Fig. 1). Lighting is supplied by several LEDs and spotlights, respectively. The camera is oriented in a way that ...

WhatsApp: +86 18037808511

A scaleup model was developed based on data of DEM simulation to quickly predict ball milling performance for different mill design and operation parameters. The ball milling performance was characterized by grinding rate and power draw. The damping energy of ground particles obtained from DEM simulation was used to characterise particle ...

WhatsApp: +86 18037808511

In this study, series of dry grinding tests were performed in a prototype horizontal stirred mill (42 L) to investigate the effects of operating parameters such as stirrer speed, feed rate, media ...

WhatsApp: +86 18037808511

The paper is aimed to investigate the influence of operating parameters on dry fine grinding of calcite in a laboratory scale conventional ball mill. Within the context, the influence of operating ...

WhatsApp: +86 18037808511

A tumbling mill is a collective name for the generally known ball mills, rod mills, tube mills, pebble mills and autogeneous mills. For all these kinds of mills the mechanics can be dealt with together, there being no substantial difference in the grinding process.

WhatsApp: +86 18037808511

The PM 300 is a planetary ball mill with 2 grinding station. ... Learn More About ® LM Vertical Mill 1. Low Investment Cost. This mill itself can crush, dry, ... Both the ball and pebble mills utilize a tumbling media, ball mills with steel balls, and ... Compare this product Remove from comparison tool.

WhatsApp: +86 18037808511

This present work focuses on DEM simulations of a scale laboratory planetary ball mill through DEM Altair software to optimize and modulate the milling parameters. The simulation results show a good agreement with the experiments. The numerical model is shown to be a promising tool for the knowledge of dry milling in a planetary ball mill.

WhatsApp: +86 18037808511

Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary greatly within the ball charge.

WhatsApp: +86 18037808511

(translated from German with Google Translate ) Tumbling mills ( balls mills, media mills, rod mills, etc.) are proven devices for the fine grinding of medium to very hard materials.

WhatsApp: +86 18037808511

Vertical stirred mills have been widely applied in the minerals industry, due to its greater efficiency in comparison with conventional tumbling mills. In this context, the agitator liner wear plays an important role in maintenance planning and operational costs. In this paper, we use the discrete element method (DEM) wear simulation to evaluate the screw liner wear. Three different mill ...

WhatsApp: +86 18037808511

The mineral processing industry has seen an increased use of vertical stirred mills, owing to the ineficiency of ball mills for fine grind applications. The difficulty encountered in fine grinding is the increased resistance to comminute small particles compared to coarse particles.

WhatsApp: +86 18037808511