Sulphur has to be removed first in a separate process. Magnesium powder is blown through the molten iron and the sulfur reacts with it to form magnesium sulfide. This forms a slag on top of the iron and can be removed. ... Avoiding the pollution problems in the extraction of iron from the ore. Not having to find space to dump the unwanted iron ...

WhatsApp: +86 18037808511

Extraction of iron or its metallurgy is the process of obtaining this metal in a form where it can be put to practical use, and this process of extraction consists of three stages: Ore dressing, Reduction of ores and Iron production. Extraction of Iron from its ores The ore dressing

WhatsApp: +86 18037808511

The advantages of extracting iron ore. The mining of iron ore offers a plethora of advantages, which has contributed to the process being one of the most sought after in the mining sector. To begin, the extraction of iron from its ores is a fundamental step in the manufacturing of steel. Steel is an essential material in the construction of ...

WhatsApp: +86 18037808511

Smelting. Electric phosphate smelting furnace in a TVA chemical plant (1942) Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. [1] It is a form of extractive metallurgy that is used to obtain many metals such as iron, copper, silver, lead and zinc.

WhatsApp: +86 18037808511

The primary methods used to extract minerals from the ground are: Underground miningSurface (open pit) miningPlacer mining The location and shape of the deposit, strength of the rock, ore grade, mining costs, and current market price of the commodity are some of the determining factors for selecting which mining method to metallic ores found in veins deep under the Earth's ...

WhatsApp: +86 18037808511

Iron ore is ~94% of the billion tons of metals mined in 2019, and 98% of that iron goes directly into steel production. Metal extraction process. What is extraction? It is the process of preparing and separating impurities from mined products to refine the valuable metal within the ore.

WhatsApp: +86 18037808511

The extraction of iron from its ores is quite a technical process. The iron ore is first roasted in air to produce iron (III) oxide which is mixed with coke and limestone and then further heated to a very high temperature in a blast furnace. These materials are loaded into the blast furnace from the top while a blast of hot air is introduced ...

WhatsApp: +86 18037808511

Iron Extraction Process. In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron ore. ... At the bottom of the furnace the iron ore is chemically reduced. The blast reacts with the coke; carbon dioxide and carbon monoxide are formed at temperatures of up to 2000 °C.

WhatsApp: +86 18037808511

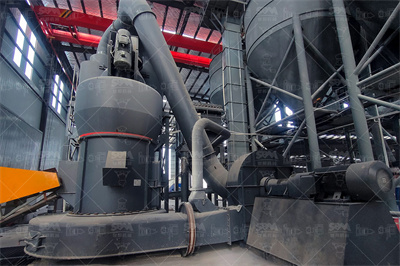

The basic extraction of metals from ores has the following steps. Grinding and Crushing. The bigger chunks of the ore extracted are crushed and ground in ball mills and crushers. It helps to increase the surface area of the chunks for better chemical actions later. In technical terms, it is called pulverisation.

WhatsApp: +86 18037808511

We have investigated Bayer red mud with a TFe content of % collected from the Pingguo area of China, and have found that iron is the key metal affecting the extraction of valuable components such as Sc, Ti, and Ga. Based on this, an efficient process of roasting with calcium salt and magnetic separation has been proposed to extract iron from the Bayer red mud. Coke, calcium chloride, and ...

WhatsApp: +86 18037808511

The main characteristic of the process is the iron sulfates decomposition during roasting ... Basturkcu and Acarkan used sulfuric digestion followed by roasting and leaching for nickel and iron extraction from a nickel laterite ore containing mainly quartz and goethite. These authors reported that extractions around 60, 40, and 78 pct of nickel ...

WhatsApp: +86 18037808511

The Phalaborwa Rare Earths project will use extraction technology to reprocess historic phosphate mining waste to produce rare earth metals. ... and transition from an exporter of iron ore to ...

WhatsApp: +86 18037808511

solventextraction or ionexchange. The uranium industry was the first hydrometallurgical industry to make extensive use of these two unit operations. The active agent in the solventextraction process is usually an organic amine salt, diluted in kerosene, that can selectively extract the uranium ions into an organic complex which is insoluble ...

WhatsApp: +86 18037808511

Herein, the vanadium and iron extraction of VBT samples was calculated as follows: (1) η y, F e = (1W 1 × β 1 W 0 × β 0) × 100 % where, η was the extraction rate of vanadium and iron (%), W 0 and W 1 were the weight of VBT ore and the leaching residue, respectively (g). β 0 and β 1 were the content of vanadium and iron in VBT ore and ...

WhatsApp: +86 18037808511

Introduction Iron ore. Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined. Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)·n(H 2 O)) or siderite (FeCO 3).Hematite and magnetite are the most common ...

WhatsApp: +86 18037808511

Iron, atomic number 26, is the most abundant element on earth by mass. It belongs to the 3d series or first transition series of the periodic table. Pure metallic iron is not usually found in the earth's crust. Therefore, extracting metal from ore is the only way to obtain usable iron. Extraction of iron from its ore is a lengthy process and ...

WhatsApp: +86 18037808511

Wrought iron is an iron alloy with a very low carbon content, in contrast to cast iron. It is a tough, malleable, ductile, and corrosionresistant material. Iron Extraction Procedure. The process of extracting iron from its ore involves crushing the ore to a powder and then heating it in a furnace with a carbon source.

WhatsApp: +86 18037808511

Figure 5 shows the effect of the acid concentration on the leaching of silicatebased ore. The iron extraction increased from % ( mol/L) to % ( mol/L) and then remained constant as the concentration of H+ increased. ... For this reason, as more reduction was added into the leaching process, the extraction rate decreased, and ...

WhatsApp: +86 18037808511

Casa de Pedra Introduction Iron is one of the major constituents of the rocks in the Earth's crust and is always present in varying degrees in sedimentary formations.

WhatsApp: +86 18037808511

The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Chapter 7 (Stace, 2014) on Iron Ore Extraction Techniques).The LCA boundary used in this study is shown in Fig. mining method selected depends on a variety of factors, including the nature and location of the deposit, and the size, depth, and grade of the deposit.

WhatsApp: +86 18037808511

The extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag. What happens in the Blast Furnace? The purpose of a Blast Furnace is to reduce the concentrated ore chemically to its liquid metal state.

WhatsApp: +86 18037808511

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

WhatsApp: +86 18037808511

In this research, the coarse manganese concentrate was collected from a manganese ore concentrator in Tongren of China, and the contents of manganese and iron in coarse manganese concentrate were % and %, respectively. The majority of the minerals in coarse manganese concentrate occur in rhodochrosite, limonite, quartz, olivine, etc. Calcium chloride, calcium hypochlorite, coke, and ...

WhatsApp: +86 18037808511

Extracting copper from its ores. The method used to extract copper from its ores depends on the nature of the ore. Sulfide ores such as chalcopyrite ((CuFeS_2)) are converted to copper by a different method from silicate, carbonate or sulfate ores. Chalcopyrite (also known as copper pyrites) and similar sulfide ores are the commonest ores of ...

WhatsApp: +86 18037808511

The Ore Extraction and Refining Process Before iron ore can be used in a blast furnace, it must be extracted from the ground and partially refined to remove most of the impurities. Leaning on his long tongs, this young iron puddler's helper posed for this photograph in the early 1860s, when the Sons of Vulcan was a young union.

WhatsApp: +86 18037808511

First stage, which is the extraction process, Iron ore tailings. A lot of material is left unused during iron extraction, because of less concentration of the intended mineral. During the processing of the extracted ore, it involves milling and grinding which causes generation of tailing waste in the form of slurry. The specific characteristics ...

WhatsApp: +86 18037808511

Solvent Extraction Tests. The separation of iron from the original PLS was studied by modifying the initial pH of the aqueous solution. The final pH and the extraction of metals in the organic phase are presented in Table seen in the table, the presence of the organic mixture caused the acidification of aqueous phase, and the value of the final pH was significantly lower.

WhatsApp: +86 18037808511

Extracting iron from iron ore using a blast furnace Iron is extracted from iron ore using carbon and limestone inside a blast furnace. Iron ores are present as iron oxides in rocks like magnetite and haematite. These are mined from the ground in massive open cast mines in the USA, Canada, Brazil, Australia, China, Russia and Sweden. The iron is ...

WhatsApp: +86 18037808511

The extraction of iron is mainly from its oxide,, hematite, and the process of extraction of iron involves the following steps. Concentration Concentration is the process of removing unwanted and useless material from ore.

WhatsApp: +86 18037808511

Iron ore mining is the process of extracting iron from its natural form, which is found in rocks and minerals. The process begins by removing the topsoil from the area to be mined. This soil is then replaced and compacted to make sure that there is no waterlogging or runoff. The next step is to drill holes into the rock, so that explosives can ...

WhatsApp: +86 18037808511